Energy Saving Rotary Air Heat Transfer Heat Exchanger

Features of Hodream rotary heat exchanger

- Synthetical material with high hydrophilicity. 3A molecular sieve can effectively avoid secondary pollution.

- Advanced technology and special rotary heat exchanger design, high efficiency up to 90%, sensible heat and enthalpy recovery available.

- Double sealing system and purge sector, air leakage less than 0.3% when temperature different is above 200Pa

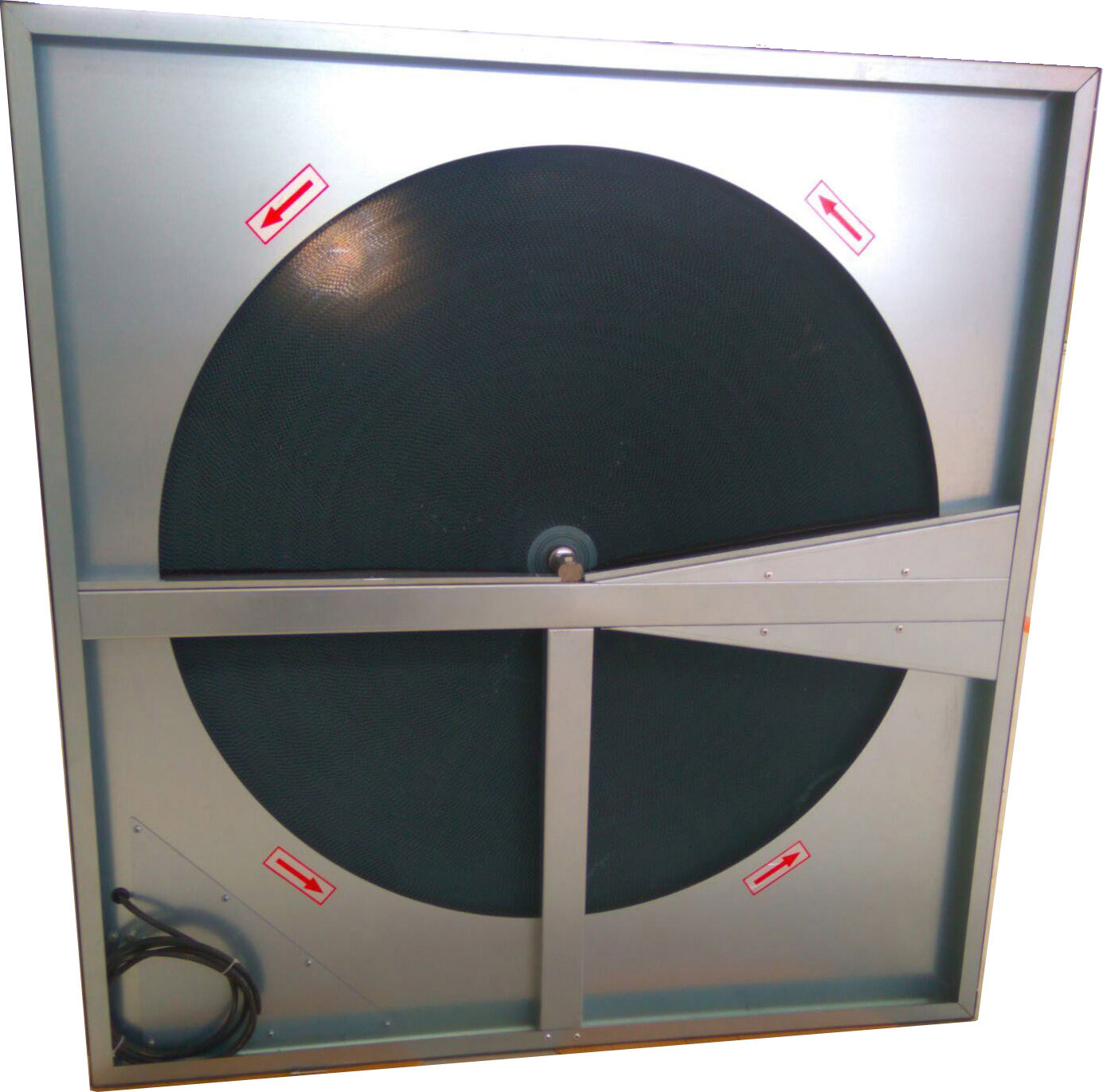

- Various installation type and motor position available, convenient for each project case.

- Built in top quality imported motor from Germany, CE and ce certificated.

90% efficiency of Hodream rotary heat exchanger

Rotary heat exchanger, also known as heat recovery wheel, thermal wheel and enthalpy wheel, is a type of energy recovery heat exchanger positioned within

the supply and exhaust air streams of an air handling system, or in the exhaust gases of an industrial process, in order to recover the heat energy.

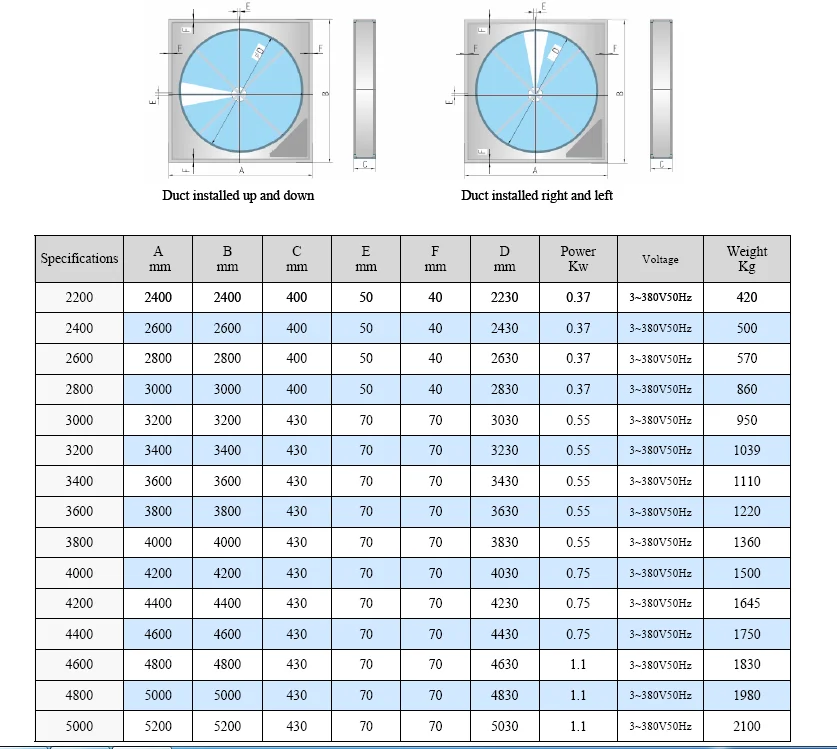

Specifications and dimensions of Hodream rotary heat exchanger

Working principle of Hodream rotary heat exchanger

Rotary heat exchanger is composed of alveolate heat wheel, case, drive system and sealing parts. The exhaust and outdoor air pass through half of the wheel separately, when

the wheel rotates, the heat and moisture are exchanged between the exhaust and outdoor air. The energy

recovery efficiency is up to 70% to 90%.

Product details of Holtop rotary heat exchanger

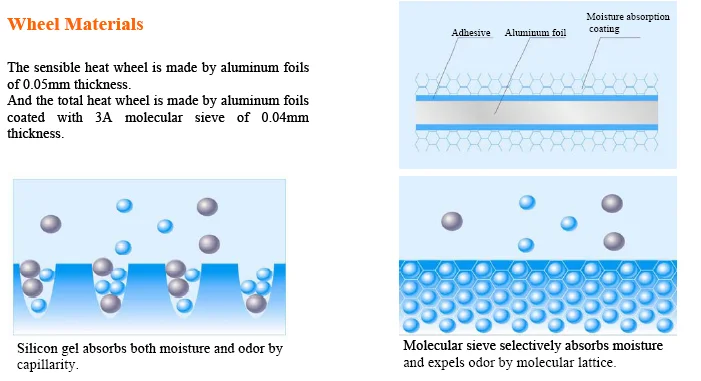

Wheel materials

The sensible heat recovery wheel is made by aluminum foils of 0.05mm thickness. And the enthalpy recovery wheel is made by aluminum foils coated with 3A molecular sieve of 0.04mm.

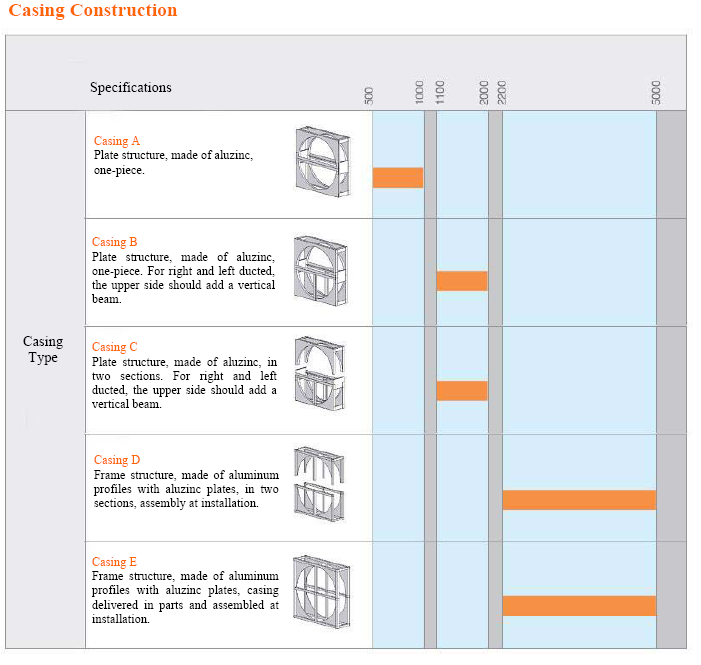

Casing construction

Casing construction

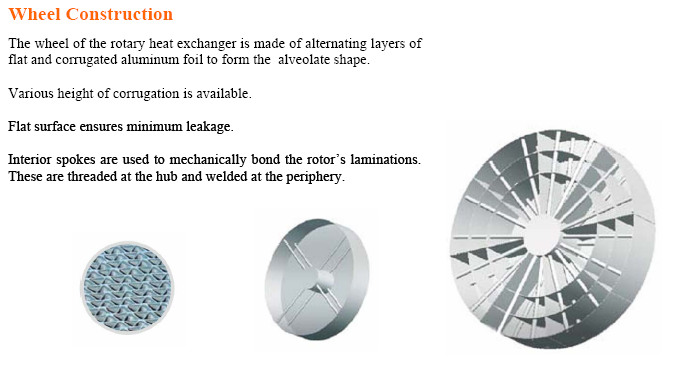

Wheel Construction

The wheel of the rotary heat exchanger is made of alternating layers of flat and corrugated aluminum foil to form the alveolate shape. Various

height of corrugation is available. Flat surface ensures minimum leakage. Interior spokes are used to mechanically bond the rotor’s laminations.

These are threaded at the hub and welded at the periphery.

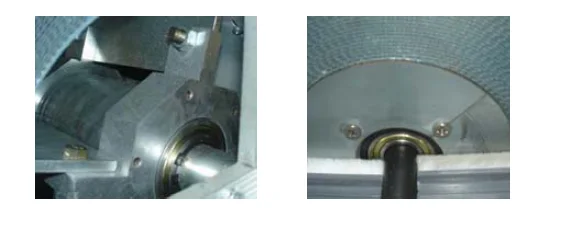

Bearing and drive system

The hub of the wheel is equipped with life-time- lubricated ball bearing or roller bearing, and with covers at both sides. No maintenance is required under normal usage.

- V-belt with big interface. Long service life.

- Spring shock absorber insures steady operation.

- Integrated motor and speed reducer free from maintenance.

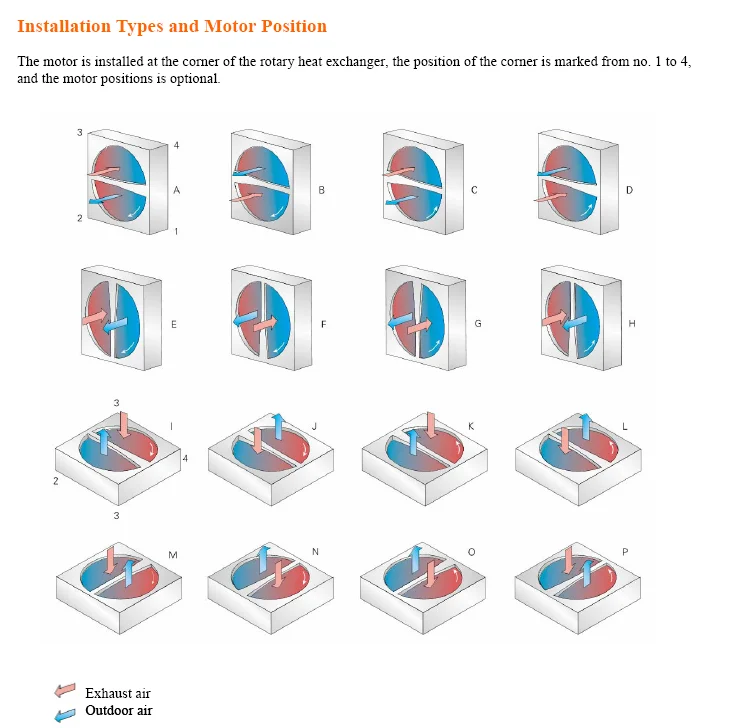

Installation types and motor position

The motor is installed at the corner of the rotary heat exchanger, the position of the corner is marked from no. 1 to 4, and the motor position is optional.

SPECIFICATIONS AND DIMENSIONS

|

Casing Type A

|

|||||||||

| Specifcations |

A mm |

B mm |

B1 mm |

B2(A1) mm |

F mm |

D mm |

Power Kw |

Voltage | N.W. Kg |

| 400 | 504 | 554 | 277 | 68 | 32 | 400 | 0.09 | 3~380V50Hz | 32 |

| 500 | 600 | 600 | 312 | 68 | 32 | 530 | 0.09 | 3~380V50Hz | 42 |

| 600 | 700 | 700 | 350 | 68 | 32 | 630 | 0.09 | 3~380V50Hz | 59 |

| 700 | 800 | 800 | 400 | 68 | 32 | 730 | 0.09 | 3~380V50Hz | 71 |

| 800 | 900 | 900 | 450 | 68 | 32 | 830 | 0.09 | 3~380V50Hz | 82 |

| 900 | 1030 | 1030 | 515 | 98 | 32 | 930 | 0.09 | 3~380V50Hz | 102 |

| 1000 | 1130 | 1130 | 565 | 98 | 32 | 1030 | 0.09 | 3~380V50Hz | 130 |

|

Casing Type B and Type C

|

|||||||||

| Specifcations |

A mm |

B mm |

B1 mm |

F mm |

D mm |

Power Kw |

Voltage | Up-down type/Right-left type N. W. Kg | |

| 1100 | 1230 | 1230 | 615 | 32 | 1130 | 0.09 | 3~380V50Hz | 151 | |

| 1200 | 1330 | 1330 | 695 | 32 | 1230 | 0.18 | 3~380V50Hz | 169 | |

| 1300 | 1430 | 1430 | 745 | 32 | 1330 | 0.18 | 3~380V50Hz | 190 | |

| 1400 | 1530 | 1530 | 765 | 32 | 1430 | 0.18 | 3~380V50Hz | 205 | |

| 1500 | 1630 | 1630 | 766 | 42 | 1530 | 0.18 | 3~380V50Hz | 212/220 | |

| 1600 | 1730 | 1730 | 816 | 42 | 1630 | 0.18 | 3~380V50Hz | 230/239 | |

| 1700 | 1830 | 1830 | 866 | 42 | 1730 | 0.25 | 3~380V50Hz | 256/266 | |

| 1800 | 1930 | 1930 | 916 | 47 | 1830 | 0.25 | 3~380V50Hz | 283/293 | |

| 1900 | 2030 | 2030 | 966 | 47 | 1930 | 0.25 | 3~380V50Hz | 301/320 | |

| 2000 | 2130 | 2130 | 1016 | 47 | 2030 | 0.25 | 3~380V50Hz | 358/370 | |

| If the casing is with side panel, revise the dimension as per formula: A+4, B+4, B1+2, F+2. | |||||||||

| Specifcations 1100-1400 are for casing B, specifcations 1500-2000 are for casing B or C. | |||||||||

|

Casing Type D and Type E

|

|||||||||

| Specifcations |

A mm |

B mm |

C mm |

E mm |

F mm |

D mm |

Power Kw |

Voltage | Weight Kg |

| 2200 | 2400 | 2400 | 400 | 50 | 40 | 2230 | 0.37 | 3~380V50Hz | 420 |

| 2400 | 2600 | 2600 | 400 | 50 | 40 | 2430 | 0.37 | 3~380V50Hz | 500 |

| 2600 | 2800 | 2800 | 400 | 50 | 40 | 2630 | 0.37 | 3~380V50Hz | 570 |

| 2800 | 3000 | 3000 | 400 | 50 | 40 | 2830 | 0.37 | 3~380V50Hz | 860 |

| 3000 | 3200 | 3200 | 430 | 70 | 70 | 3030 | 0.55 | 3~380V50Hz | 950 |

| 3200 | 3400 | 3400 | 430 | 70 | 70 | 3230 | 0.55 | 3~380V50Hz | 1039 |

| 3400 | 3600 | 3600 | 430 | 70 | 70 | 3430 | 0.55 | 3~380V50Hz | 1110 |

| 3600 | 3800 | 3800 | 430 | 70 | 70 | 3630 | 0.55 | 3~380V50Hz | 1220 |

| 3800 | 4000 | 4000 | 430 | 70 | 70 | 3830 | 0.55 | 3~380V50Hz | 1360 |

| 4000 | 4200 | 4200 | 430 | 70 | 70 | 4030 | 0.75 | 3~380V50Hz | 1500 |

| 4200 | 4400 | 4400 | 430 | 70 | 70 | 4230 | 0.75 | 3~380V50Hz | 1645 |

| 4400 | 4600 | 4600 | 430 | 70 | 70 | 4430 | 0.75 | 3~380V50Hz | 1750 |

| 4600 | 4800 | 4800 | 430 | 70 | 70 | 4630 | 1.1 | 3~380V50Hz | 1830 |

| 4800 | 5000 | 5000 | 430 | 70 | 70 | 4830 | 1.1 | 3~380V50Hz | 1980 |

| 5000 | 5200 | 5200 | 430 | 70 | 70 | 5030 | 1.1 | 3~380V50Hz | 2100 |

| If casing is with side panel, revise the dimension as per formula: A+4, B+4, B1+2, F+2 | |||||||||