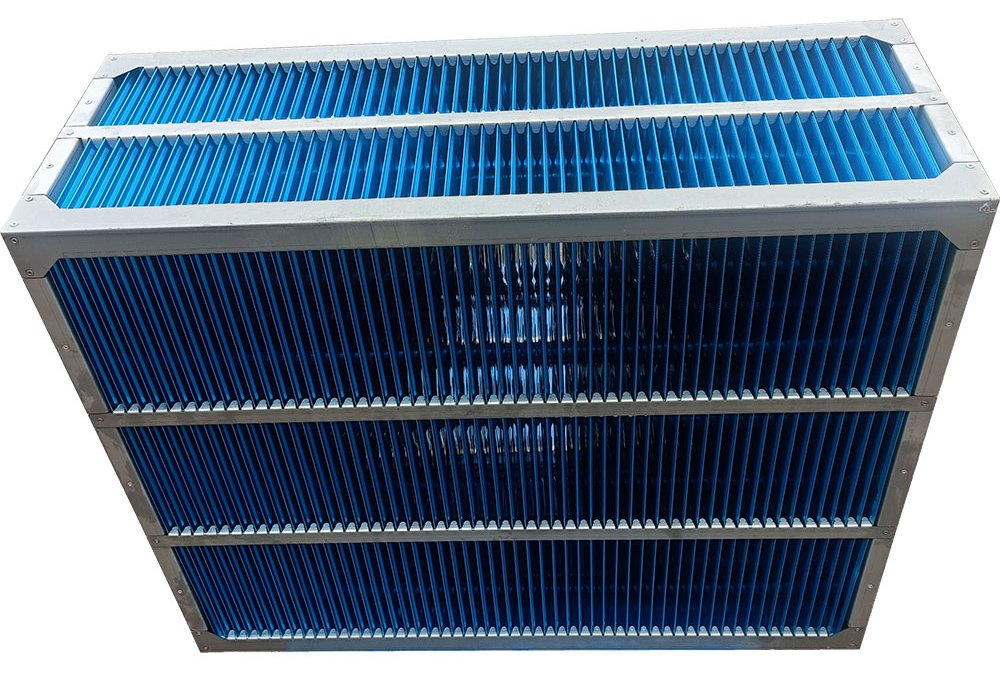

cross flow hydrophilic aluminum plate air to air heat recovery exchanger core

Introduction of Heat Recovery Core

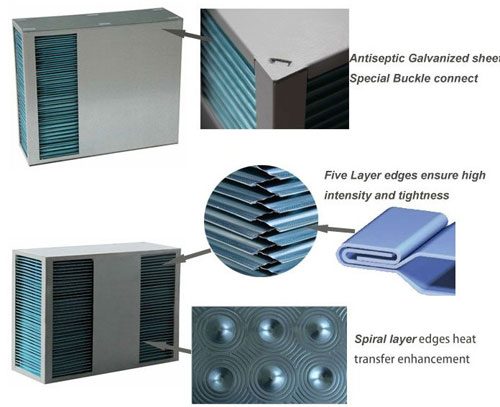

The Air to air heat recovery exchanger core series is made of anti-corrosive hydrophilic aluminum foil and hot-dip Al-Zn alloy coated steel sheet framework, process by special technology, with high heat transfer efficiency, also easy to maintain and have long service life.

Main Features of Heat Recovery Core

1)Sensible heat recovery

2) Total separation of fresh air & exhaust air streams

3) Heat recovery efficiency up to 85%

4) 2-side press shaping

5) Double folded edge

6) Completely joint sealing.

Model ofHeat Recovery Core

| A (mm) | B (mm) | C (mm) | D (mm) plate distance | E (mm) | F (mm) |

| 200~1000 | 140~600 | 100~1000 | 2.5~8.0 | 16~30 | A*(1/5~1/2) |

Working Principle of Heat Recovery Core

The counter flow and sensible heat exchanger. Two air streams are passed though the separate air channels and exchanged the energy. This design not only improves heat transfer area, but also recovery energy efficient.

Workshop of Heat Recovery Core

Package of Heat Recovery Core

Applied Range of Heat Recovery Core

The air to air heat exchanger core is the major part of telecom cabinet or base station ventilation, for air volumes up to 5000 m3/h,The heat exchanger controlled the ventilation, recover the heat energy in winter and cold energy in summer, not only save the energy but also give station for fresh air, ensure the normal operation of equipments.